Difference between revisions of "Liquid Metal"

| Line 33: | Line 33: | ||

<gallery> | <gallery> | ||

LIQ_0045.jpg | LIQ_0045.jpg|Small test pour | ||

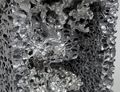

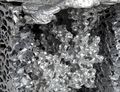

LIQ_1701.jpg | LIQ_1701.jpg|Material binding tests | ||

LIQ_1704.jpg | LIQ_1704.jpg|Material binding test | ||

LIQ_1769.jpg | LIQ_1769.jpg|Material binding test | ||

LIQ_1798.jpg | LIQ_1798.jpg|Glow in the dark ball light test | ||

LIQ_1950.jpg | LIQ_1950.jpg|Using a cement cylinder as mold | ||

LIQ_0046.jpg | LIQ_0046.jpg|Initial stool with failed legs | ||

LIQ_2186.jpg | LIQ_2186.jpg|Stool prototype | ||

LIQ_2190.jpg | LIQ_2190.jpg|Seat casting | ||

LIQ_0090.jpg | LIQ_0090.jpg|Water bead tank (left), refractory (right) | ||

LIQ_0077.jpg | LIQ_0077.jpg|Refractory running | ||

LIQ_0078.jpg | LIQ_0078.jpg|Refractory open | ||

LIQ_0194.jpg | LIQ_0194.jpg|Plaster refractories have a short lifespan. Ceramic tile shield over where jet blast hits the wall | ||

LIQ_0198.jpg | LIQ_0198.jpg|Ceramic tile shield over where jet blast hits the wall | ||

LIQ_1948.jpg | LIQ_1948.jpg|Water bead tank with retaining wall inserts | ||

{...} | {...} | ||

</gallery> | </gallery> | ||

Revision as of 19:33, 21 July 2018

Liquid Metal was created for "Collection 3, Part 3: Domestic Appeal" curated by Matylda Krzykowski for Chamber Gallery, New York and exhibited from March 3 to April 22, 2017. Two stools and one light were made.

These pieces were created by pouring aluminum just above the melting point into a tank of water gel beads. It is poetic that an ephemeral material like water can be used to form a rigid material like aluminum.

Production

A rudimentary refractory furnace was made using plaster and vermiculite. The heat source was a propane jet made from a steel tube with a transverse section running through it. This transverse section has an outlet pointing towards the front of the tube where the pressurized propane shoots out, this draws air from behind it into the tube and creates the jet action.

When the molten aluminum is poured into the water bead tank it flows into the negative space between the beads and at the same time heat is quickly pulled from the metal causing it to solidify as it descends.

Aluminum foam was used to make the legs of the stool by inserting the loose foam pieces into the gel bead tank. The beads hold the loose pieces in place as the molten aluminum flows into the cavities of the foam. As it cools the metal shrinks slightly, thus binding these loose pieces together.